- AI

- DOWNTIME REDUCTION

- AIOPS

How to reduce downtimes with AI in your business

Oct 7, 2025

-

Emilia Skonieczna

-

8 minutes

Take a look around and see what's happening right now: AI is everywhere. It's even making decisions for us - some small, others life-changing, like in medicine or law. The chances that your competitors are already using AI to work faster, optimize processes, and deliver more value are not just high - they're almost certain.

But here's the catch: even the smartest AI system is useless if it's down. Downtime kills efficiency, slows innovation, and drains money. Do you want that? Probably not.

So, how do you make sure your AI works for you 24/7?

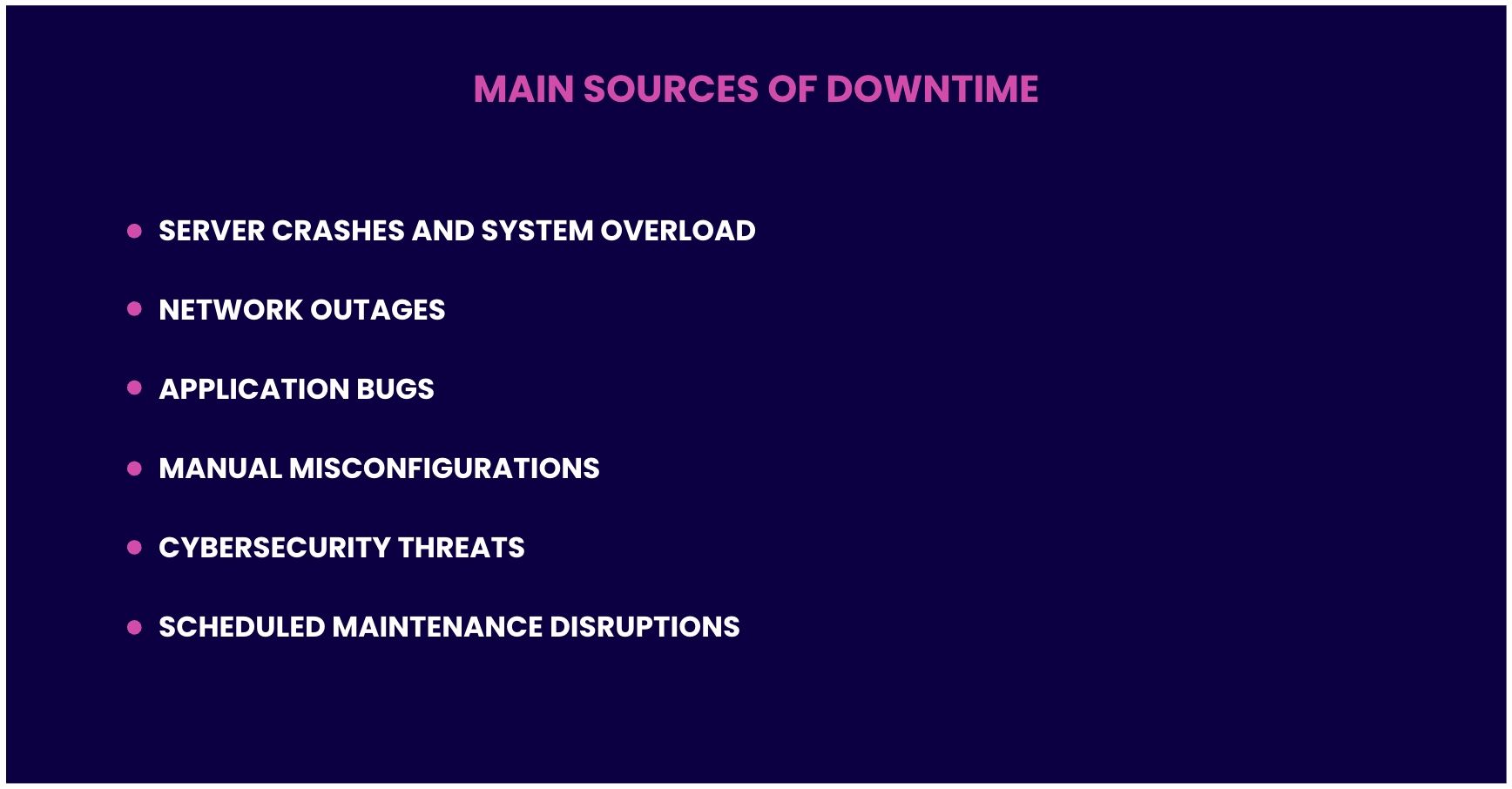

Downtime happens when critical systems or tools stop working as they should. It can be caused by a wide range of factors, including overloaded servers, unstable networks, or hidden software bugs.

Sometimes the reason is external, such as a cyberattack, while other times it's internal, like a simple misconfiguration.

Even scheduled maintenance can disrupt daily operations.

The main sources of unplanned downtime often come from infrastructure and process vulnerabilities. Server failures or network outages can instantly block access to essential tools, while poorly tested software updates or application bugs create cascading disruptions across operations.

Other common sources are human mistakes, such as incorrect manual settings. We also can't forget about growing cybersecurity threats, like ransomware, that can freeze entire systems.

Even planned downtime can result in unexpected breaks in business continuity - but only if it isn't supported by effective maintenance strategies.

When hardware fails - whether it's servers crashing or storage becoming overloaded - the impact quickly spreads across workflows, delaying projects and increasing costs. On the software side, bugs, outdated versions, or broken integrations reduce reliability and make it harder to keep operations running without disruptions.

Human errors, such as a single misconfiguration or delayed response, can turn minor issues into major breakdowns.

If you combine these factors, you'll understand why downtime remains one of the most persistent challenges for businesses adopting advanced technologies. That's why many companies are turning to predictive maintenance strategies and AI-driven monitoring tools.

Artificial Intelligence is changing how companies handle system reliability. Instead of reacting to failures after they happen, AI allows businesses to use predictive approaches to detect problems before they escalate.

If you mix AI capabilities with advanced monitoring and data learning, you'll get smooth operations and minimized downtime risks.

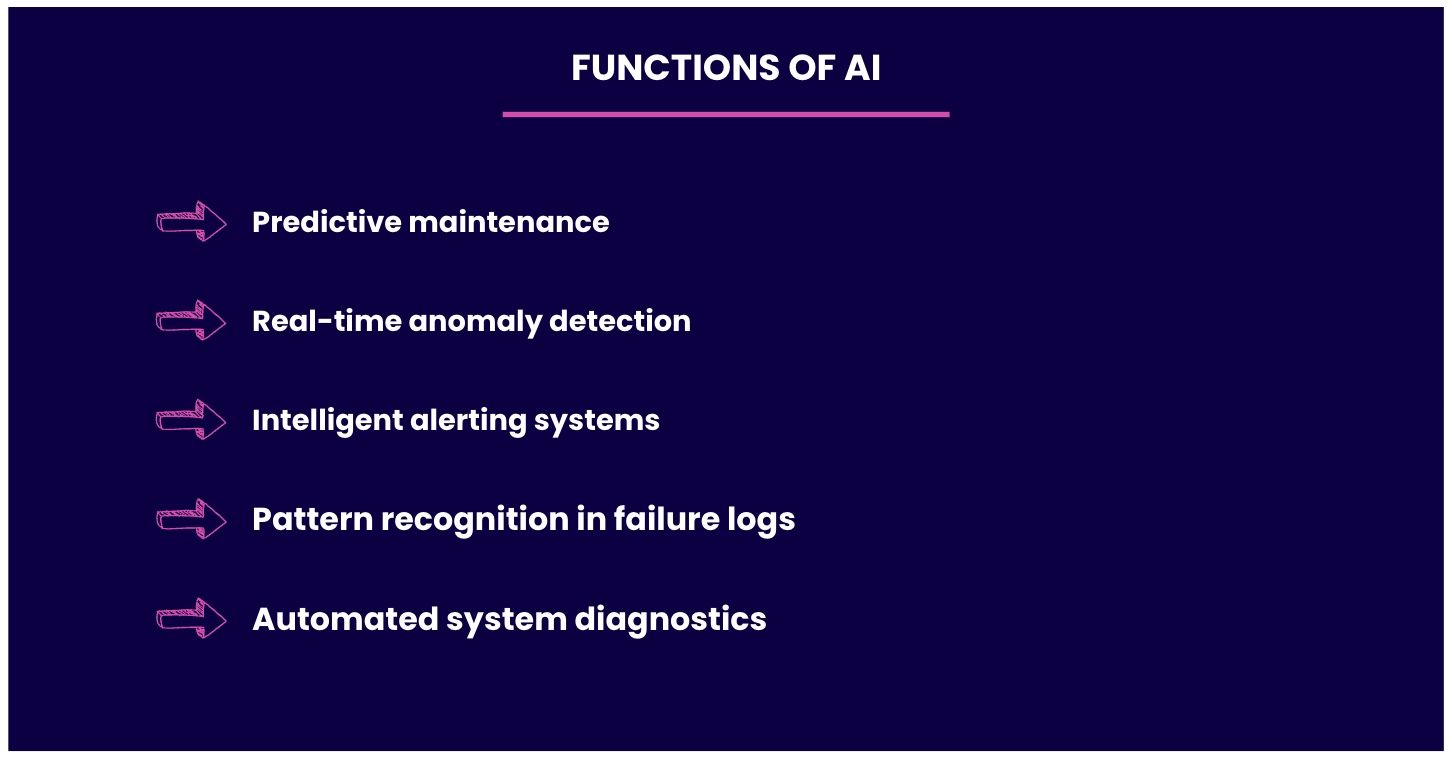

AI plays a critical role in avoiding system failures - thanks to its ability to continuously monitor infrastructure and applications.

Let's look at it this way:

Machine learning models analyze real-time data to detect anomalies early, while pattern recognition in failure logs reveals recurring problems.

Intelligent alerting systems notify teams before small problems turn into major outages.

Combine all of this with automated system diagnostics, and you create a proactive defense layer that reduces reliance on reactive fixes and keeps business operations stable.

Predictive maintenance reduces risks by shifting from reactive to proactive. Instead of waiting for problems, AI uses fault prediction and anomaly detection to forecast equipment failures or software malfunctions in advance.

It also looks at historical maintenance logs to catch warning signals that people would likely miss.

The result? Companies are able to create optimized maintenance schedules, ensuring that maintenance is performed at the right time rather than too early or too late. This not only reduces maintenance costs but also minimizes downtime and leads to improved operational efficiency.

Why use AI to reduce downtime? The answer is simple: it's the easiest way to avoid outages and the mess they leave behind.

With predictive maintenance models, smart monitoring, and automated failover, companies can reduce incident resolution times by up to 70% and eliminate costly interruptions.

When you realize that downtime costs an average of $5,600 per minute (according to Gartner), it becomes clear that minimizing disruptions not only improves efficiency but also supports better compliance and leads to increased customer satisfaction and trust.

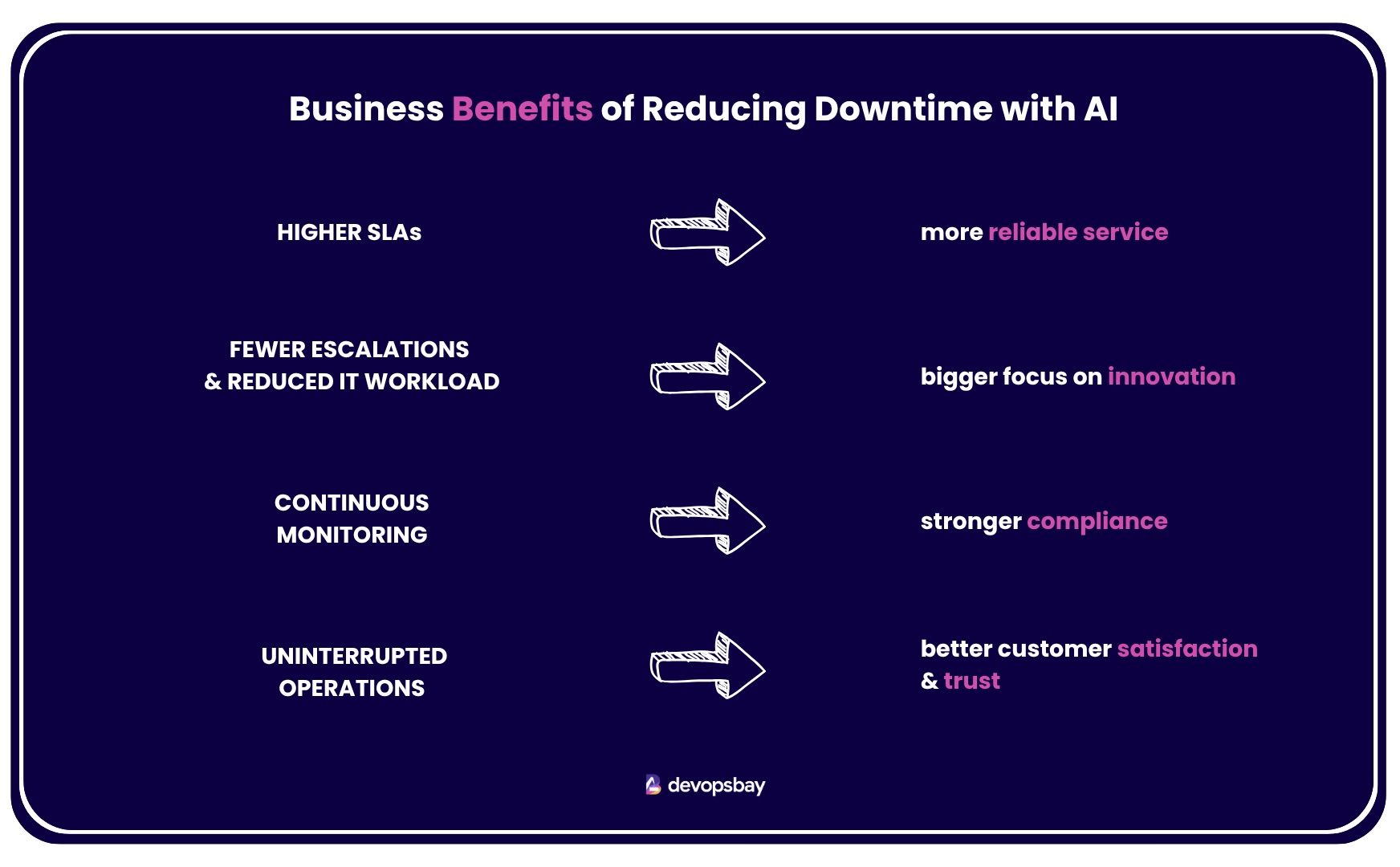

Using AI to improve uptime directly impacts both top-line and bottom-line results. Higher uptime SLAs mean that business can avoid unexpected downtime. This leads to fewer escalations, reduced IT workload, and uninterrupted customer interactions.

The result?

Higher satisfaction, stronger trust, and more repeat business.

When critical systems perform without breakdowns, companies can keep delivering value, increase revenue, and build lasting relationships.

AI-driven predictive maintenance makes a measurable impact on business operations. Metrics like Mean Time to Detect (MTTD) and Mean Time to Resolve (MTTR) drop significantly - in fact, AI can cut resolution times by up to 70%.

With proactive maintenance actions, systems stay available longer, and continuous monitoring keeps compliance in line.

So... that means fewer breakdowns, lower costs, and better overall efficiency.

The benefits of reducing downtime with AI go far beyond cost savings.

Higher SLAs ensure reliable service

Fewer escalations and reduced IT workload free teams to focus on innovation

Continuous monitoring strengthens compliance

Uninterrupted operations result in better customer satisfaction and trust

The outcome? More resilient service delivery. It not only maintains business continuity but also builds stronger relationships and creates opportunities for the future.

Different departments across a company can use AI to minimize downtime and ensure stability:

IT Operations - predictive monitoring and root cause analysis help prevent incidents from escalating. ITSM, NOC, and AIOps rely on AI to keep systems stable 24/7

DevOps - automated deployment and recovery keep delivery pipelines on track

Cybersecurity - AI threat detection identifies risks early and supports compliance with SOC standards

Manufacturing - predictive maintenance prevents machine failures before they cause downtime

Customer Support - AI issue routing ensures requests go directly to the right team, which reduces wait times and keeps service levels high

Long story short, with AI, departments waste less time on outages and focus more on what actually matters.

AI uptime tools bring advantages that reach beyond just the tech teams. In practice, that means:

Business continuity managers get more reliable operations and fewer disruptions.

Compliance and risk teams gain peace of mind with stronger monitoring and reporting.

Finance teams see the impact in reduced downtime costs and better ROI.

Customer support enjoys uninterrupted services, which helps build trust and loyalty.

Back-office teams, supported by RPA and process automation, avoid delays that can slow down routine workflows.

Manufacturing plants use predictive maintenance systems to optimize production lines, improve accuracy, and strengthen supply chain stability.

The conclusion is simple: AI uptime tools make the whole organization more resilient.

AI isn't the only answer. While AI-driven maintenance can transform operations, there are some hurdles:

lack of clean historical data - predictive models depend on quality maintenance records; messy data = weak insights

false positives and alert fatigue - too many false alarms can make teams less responsive

complex integrations with legacy systems - bringing AI into outdated management systems can create major challenges

model drift in AI predictions - predictive maintenance tools work today, but without retraining, accuracy may decline over time

initial cost of AI implementation - predictive maintenance solutions require upfront investment before benefits start paying off

The key is balance. AI should enhance predictive approaches, not replace maintenance teams or routine maintenance entirely.

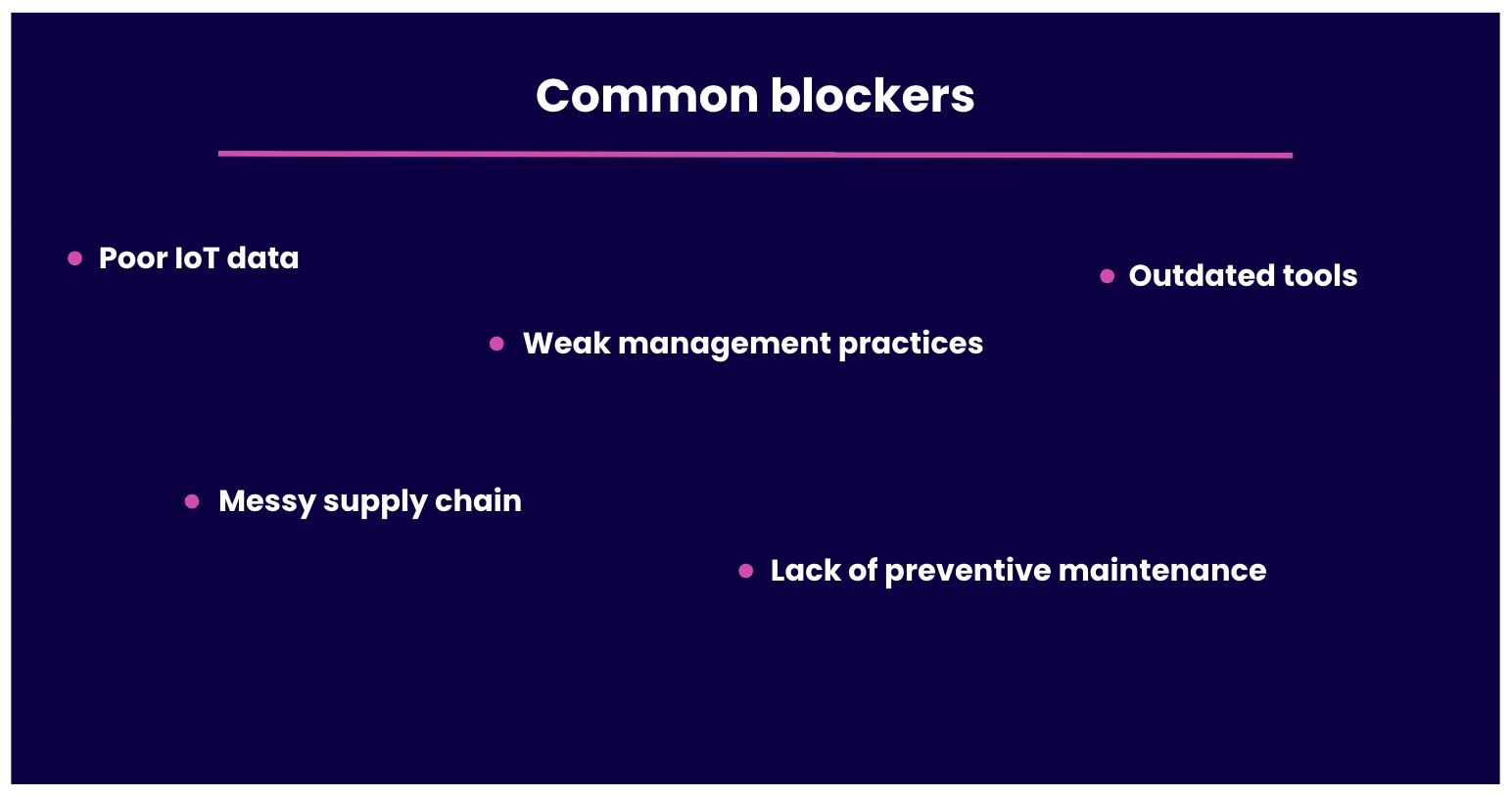

AI can't fix chaos on its own. If a business ignores preventive maintenance or has a messy supply chain, even the best systems will have trouble. Common blockers include poor IoT data, outdated tools, or weak management practices.

You'll get the best results when you combine AI with proven practices and reliable data. Without that, uptime gains will always be limited.

Overreliance is a real risk with AI - and predictive maintenance is a clear example. This approach is powerful because it can identify potential issues before they escalate. But if people treat it as a simple 'set it and forget it', then it becomes dangerous.

This shows once again that balance is the smart strategy. Mix preventive maintenance with predictive tools, so AI supports the process - but people still lead it.

Discover how AIOps is transforming DevOps by integrating AI and ML to streamline operations, increase efficiency, and enhance decision-making for better outcomes.

From innovation to intrusion? AI’s use of data scraping is raising more than a few red flags for privacy and consent - find out where the line is being crossed.

Explore how AI transforms cybersecurity with intelligent threat detection, advanced tools, and smarter defense systems. Is your organization ready to keep up?